IMO Marine Engine Regulations

Background

International Maritime Organization (IMO) is an agency of the United Nations which has been formed to promote maritime safety. It was formally established by an international conference in Geneva in 1948, and became active in 1958 when the IMO Convention entered into force (the original name was the Inter-Governmental Maritime Consultative Organization, or IMCO, but the name was changed in 1982 to IMO). IMO currently groups 167 Member States and 3 Associate Members.

IMO ship pollution rules are contained in the “International Convention on the Prevention of Pollution from Ships”, known as MARPOL 73/78. On 27 September 1997, the MARPOL Convention has been amended by the “1997 Protocol”, which includes Annex VI titled “Regulations for the Prevention of Air Pollution from Ships”. MARPOL Annex VI sets limits on NOx and SOx emissions from ship exhausts, and prohibits deliberate emissions of ozone depleting substances from ships of 400 gross tonnage and above engaged in voyages to ports or offshore terminals under the jurisdiction of states that have ratified Annex VI.

The IMO emission standards are commonly referred to as Tier I...III standards. The Tier I standards were defined in the 1997 version of Annex VI, while the Tier II/III standards were introduced by Annex VI amendments adopted in 2008, as follows:

- 1997 Protocol (Tier I)—The “1997 Protocol” to MARPOL, which includes Annex VI, becomes effective 12 months after being accepted by 15 States with not less than 50% of world merchant shipping tonnage. On 18 May 2004, Samoa deposited its ratification as the 15th State (joining Bahamas, Bangladesh, Barbados, Denmark, Germany, Greece, Liberia, Marshal Islands, Norway, Panama, Singapore, Spain, Sweden, and Vanuatu). At that date, Annex VI was ratified by States with 54.57% of world merchant shipping tonnage.Accordingly, Annex VI entered into force on 19 May 2005. It applies retroactively to new engines greater than 130 kW installed on vessels constructed on or after January 1, 2000, or which undergo a major conversion after that date. The regulation also applies to fixed and floating rigs and to drilling platforms (except for emissions associated directly with exploration and/or handling of sea-bed minerals). In anticipation of the Annex VI ratification, most marine engine manufacturers have been building engines compliant with the above standards since 2000.

- 2008 Amendments (Tier II/III)—Annex VI amendments adopted in October 2008 introduced (1) new fuel quality requirements beginning from July 2010, (2) Tier II and III NOx emission standards for new engines, and (3) Tier I NOx requirements for existing pre-2000 engines.The revised Annex VI entered into force on 1 July 2010. By October 2008, Annex VI was ratified by 53 countries (including the Unites States), representing 81.88% of tonnage.

Emission Control Areas. Two sets of emission and fuel quality requirements are defined by Annex VI: (1) global requirements, and (2) more stringent requirements applicable to ships in Emission Control Areas (ECA). An Emission Control Area can be designated for SOx and PM, or NOx, or all three types of emissions from ships, subject to a proposal from a Party to Annex VI.

Existing Emission Control Areas include:

- Baltic Sea (SOx: adopted 1997 / entered into force 2005; NOx: 2016/2021)

- North Sea (SOx: 2005/2006; NOx: 2016/2021)

- North American ECA, including most of US and Canadian coast (NOx & SOx: 2010/2012).

- US Caribbean ECA, including Puerto Rico and the US Virgin Islands (NOx & SOx: 2011/2014).

Greenhouse Gas Emissions. 2011 Amendments to MARPOL Annex VI introduced mandatory measures to reduce emissions of greenhouse gases (GHG). The Amendments added a new Chapter 4 to Annex VI on “Regulations on energy efficiency for ships”.

NOx Emission Standards

The NOx emission limits of Regulation 13 of MARPOL Annex VI apply to each marine diesel engine with a power output of more than 130 kW installed on a ship. A marine diesel engine is defined as any reciprocating internal combustion engine operating on liquid or dual fuel. There are two exceptions: engines used solely for emergencies and engines on a ships operating solely within the waters of the state in which they are flagged. The later exception only applies if these engines are subject to an alternative NOx control measure.

NOx emission limits are set for diesel engines depending on the engine maximum operating speed (n, rpm), as shown in Table 1 and presented graphically in Figure 1. Tier I and Tier II limits are global, while the Tier III standards apply only in NOx Emission Control Areas.

| Tier | Date | NOx Limit, g/kWh | ||

|---|---|---|---|---|

| n < 130 | 130 ≤ n < 2000 | n ≥ 2000 | ||

| Tier I | 2000 | 17.0 | 45 · n-0.2 | 9.8 |

| Tier II | 2011 | 14.4 | 44 · n-0.23 | 7.7 |

| Tier III | 2016† | 3.4 | 9 · n-0.2 | 1.96 |

| † In NOx Emission Control Areas (Tier II standards apply outside ECAs). | ||||

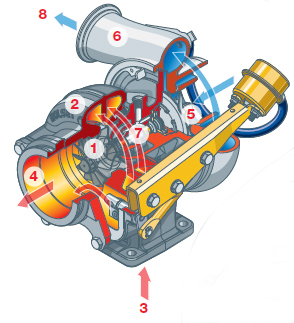

Tier II standards are expected to be met by combustion process optimization. The parameters examined by engine manufacturers include fuel injection timing, pressure, and rate (rate shaping), fuel nozzle flow area, exhaust valve timing, and cylinder compression volume.

Tier III standards are expected to require dedicated NOx emission control technologies such as various forms of water induction into the combustion process (with fuel, scavenging air, or in-cylinder), exhaust gas recirculation, or selective catalytic reduction.

Pre-2000 Engines. Under the 2008 Annex VI amendments, Tier I standards become applicable to existing engines installed on ships built between 1st January 1990 to 31st December 1999, with a displacement ≥ 90 liters per cylinder and rated output ≥ 5000 kW, subject to availability of approved engine upgrade kit.

Testing. Engine emissions are tested on various ISO 8178 cycles (E2, E3 cycles for various types of propulsion engines, D2 for constant speed auxiliary engines, C1 for variable speed and load auxiliary engines).

Addition of not-to-exceed (NTE) testing requirements to the Tier III standards is being debated. NTE limits with a multiplier of 1.5 would be applicable to NOx emissions at any individual load point in the E2/E3 cycle.

Engines are tested using distillate diesel fuels, even though residual fuels are usually used in real life operation.

Further technical details pertaining to NOx emissions, such as emission control methods, are included in the mandatory “NOx Technical Code”, which has been adopted under the cover of “Resolution 2”.

Sulfur Content of Fuel

Annex VI regulations include caps on sulfur content of fuel oil as a measure to control SOx emissions and, indirectly, PM emissions (there are no explicit PM emission limits). Special fuel quality provisions exist for SOx Emission Control Areas (SOx ECA or SECA). The sulfur limits and implementation dates are listed in Table 2 and illustrated in Figure 2.

| Date | Sulfur Limit in Fuel (% m/m) | |

|---|---|---|

| SOx ECA | Global | |

| 2000 | 1.5% | 4.5% |

| 2010.07 | 1.0% | |

| 2012 | 3.5% | |

| 2015 | 0.1% | |

| 2020 | 0.5% | |

Heavy fuel oil (HFO) is allowed provided it meets the applicable sulfur limit (i.e., there is no mandate to use distillate fuels).

Alternative measures are also allowed (in the SOx ECAs and globally) to reduce sulfur emissions, such as through the use exhaust gas cleaning systems (EGCS), aka scrubbers. For example, in lieu of using the 0.5% S fuel (2020), ships can fit an exhaust gas cleaning system or use any other technological method to limit SOx emissions to ≤ 6 g/kWh (as SO2).

Greenhouse Gas Emissions

MARPOL Annex VI, Chapter 4 introduces two mandatory mechanisms intended to ensure an energy efficiency standard for ships: (1) the Energy Efficiency Design Index (EEDI), for new ships, and (2) the Ship Energy Efficiency Management Plan (SEEMP) for all ships.

- The EEDI is a performance-based mechanism that requires a certain minimum energy efficiency in new ships. Ship designers and builders are free to choose the technologies to satisfy the EEDI requirements in a specific ship design.

- The SEEMP establishes a mechanism for operators to improve the energy efficiency of ships.

The regulations apply to all ships of 400 gross tonnage and above and enter into force from 1 January 2013. Flexibilities exist in the initial period of up to six and a half years after the entry into force, when the IMO may waive the requirement to comply with the EEDI for certain new ships, such as those that are already under construction.

In April 2018, the IMO adopted an Initial Strategy on the reduction of GHG emissions from ships [3949]. The strategy calls for strenghtening the EEDI requirements and a number of other measures to reduce emissions, such as operational efficiency measures, further speed reductions, measures to address CH4 and VOC emissions, alternative low-carbon and zero carbon fuels, as well as market-based measures (MBM).

Other Provisions

Ozone Depleting Substances. Annex VI prohibits deliberate emissions of ozone depleting substances, which include halons and chlorofluorocarbons (CFCs). New installations containing ozone-depleting substances are prohibited on all ships. But new installations containing hydro-chlorofluorocarbons (HCFCs) are permitted until 1 January 2020.

Annex VI also prohibits the incineration on board ships of certain products, such as contaminated packaging materials and polychlorinated biphenyls (PCBs).

Compliance. Compliance with the provisions of Annex VI is determined by periodic inspections and surveys. Upon passing the surveys, the ship is issued an “International Air Pollution Prevention Certificate”, which is valid for up to 5 years. Under the “NOx Technical Code”, the ship operator (not the engine manufacturer) is responsible for in-use compliance.

Thanks

Merchant navy info